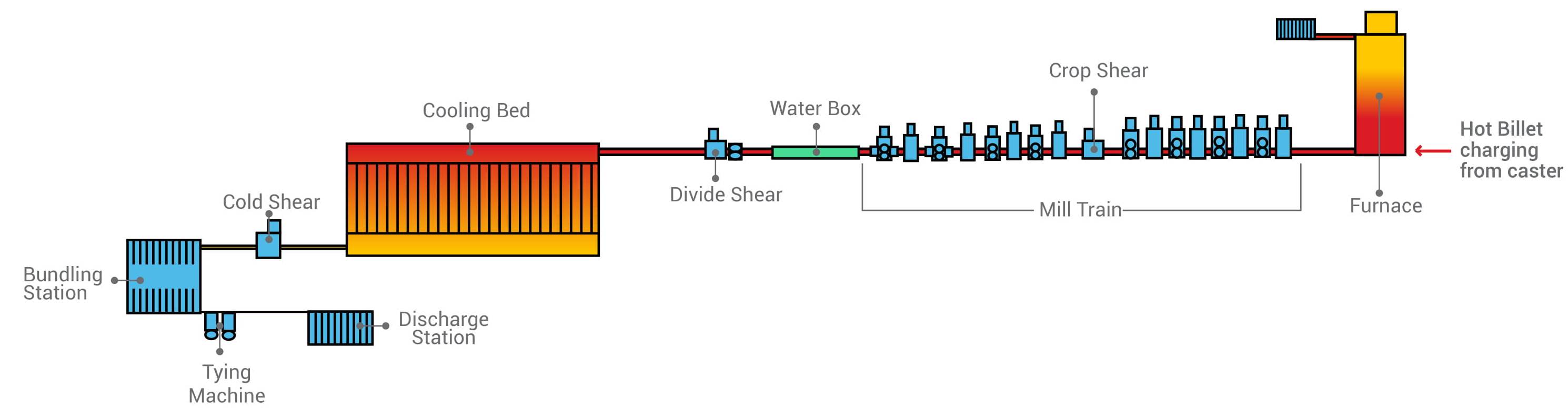

BAR MILL

SOLUTIONS WITH LATEST TECHNILOGIES WITH OPTIMIZED LAYOUT ARRANGEMENT TO ENSURE LOWEST

COST OF PRODUCTION, RELIABLE CONSISTENACE OPERATION.

All equipment are designed for high strength and reliable operation of the bar mill.To produce products to the

best tolerance and quality.

Capacity: 100,000 to 500,000

Products: 8 to 40mm

Steel Grades: Carbon steels

Capacity: 100,000 to 300,000

Products: 8 to 50mm

SBQ products: 16 to 100mm

Steel Grades: Carbon steel, Alloy steel, Stainless steel

• Conventional stands, Pre-stressed stand and Housing less rolling stands are used for wide range of application and process requirements.

• Direct hot billet rolling from Billet caster, reduces the total product cost to major extent.

• Reheating furnace operation and with efficient heating system reduces the amount of scale formed for quality /special steel products.

• hi Reversing breakdown mill and 2 hi shiftable revering mill are used for required special process requirements

• Single strand, Multi-slit and high-speed technologies make sure that the requirements of high productivity of

rebars are safely and economically guaranteed.

• Through bar-in-coil operation by Garret coiler, compact and twist free coils of bars

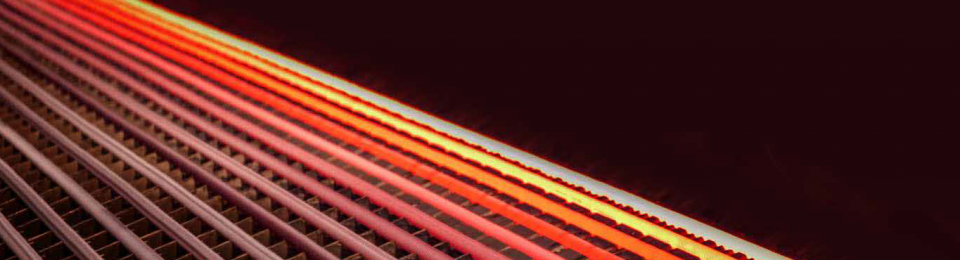

• State-of-the-art cooling technologies are available, with solid and split design nozzles to control for

thermo-mechanical rolling rebars and for quenching & tempering both carbon and alloy steels, including stainless.

• Seamless and efficient bar handling systems based on finish product requirements.